Landfill Disposal Solution for Grandville Clean Water Plant

In 2020, the had more biosolids than it could dispose of to local farms. With their storage tank close to maximum capacity and the demand for agricultural fertilizer down, they needed a way to thicken and dewater the biosolids for landfill disposal. Our clean water engineers in Grand Rapids, MI, came up with a solution to provide the plant with greater operational flexibility and multiple disposal options.

The revealed that urban and suburban sprawl, along with an increasing population, contributed to the loss of local farmland. This, in turn, gave the Grandville Clean Water Plant fewer places to dispose of biosolids. Likewise, the average distance to the nearest farm has increased over time, along with the cost of farmland disposal.

During the last few years, Michigan also experienced record or near-record amounts of rainfall. This prevented local farmers from being able to use biosolids as fertilizer on their fields. Due to regulations, biosolids can’t be used on fields that are overly saturated with water, frozen, or covered with snow.

These combined factors forced the Grandville Clean Water Plant to come up with a new disposal solution. In February 2020, the plant had accumulated about 2 million gallons of biosolids in storage with maximum capacity at only 2.5 million gallons.

Moore+Bruggink was hired to give the plant the option of landfill disposal, instead of relying exclusively on farmland disposal. To accomplish this, our Grand Rapids engineering firm developed a plan that would give the clean water plant resiliency against future cost increases and regulatory changes.

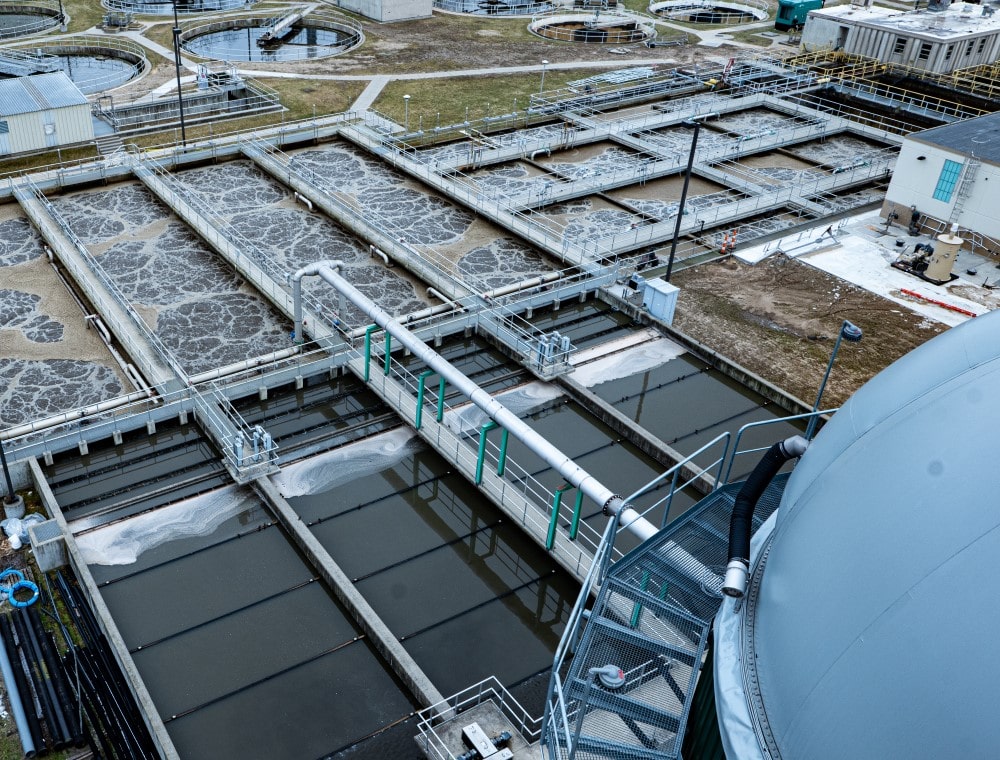

First, our clean water engineers implemented thickening equipment to compress the biosolids and remove excess liquid. The thickening equipment ensured that the biosolids were drier before entering the digester.

The Grandville Clean Water Plant is unique for its innovative egg-shaped anaerobic digester. This biodigester was part of a we worked on back in 2012 that received the Michigan Municipal League’s Community Excellence Award. Inside the biodigester are bacteria that break down organic waste, a process that produces a biogas (mostly methane) that the plant can use to generate electricity.

More solids in the biodigester leads to more biogas. To adjust for the increase in biogas, our engineers also upgraded the plant’s generator system. Moore+Bruggink added two new generators and a distributor power system. That way, the Grandville Clean Water Plant could capture and clean the extra energy to use as a natural gas for their heat and power, reducing their carbon footprint. The new update provides over 50% of the plant’s required power.

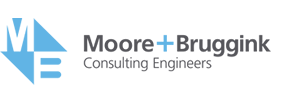

For one of the final steps in the process, our clean water engineers added two new dewatering centrifuges for the biosolids leaving the digester. Similar to how a washing machine has a final spin cycle to remove water, a dewatering centrifuge spins out biosolids at high speeds. This ensures that the biosolids are dry enough to send to the landfill for disposal. From there, the biosolids are distributed down to conveyors that lead to dumpsters ready for haulers.

By implementing thickening and dewatering equipment and facilities, we were able to help the plant pivot to a new disposal method. We also helped the Grandville Clean Water Plant generate more electricity, adding a new chapter to their legacy of environmental sustainability and energy efficiency.

Have questions? Contact Moore+Bruggink at (616) 363-9801 to speak with our clean water engineers in Grand Rapids, MI.